About three times a day, Rich Benoit gets a call to his auto shop, The electrified garage, from the owner of an older Tesla Model S whose car battery began to fail. The battery, which used to provide several hundred miles of range, suddenly can only last 50 miles on a single charge. These cars are often out of warranty, and the cost to replace the battery can exceed $15,000.

For most products, repair is a more affordable option than replacement. And in theory, many of these Tesla batteries can be fixed, says Benoit, who runs one of the few Tesla-focused independent repair shops in the United States. But because of the time and training involved, the safety considerations and the complexity of the repair, Benoit said the bill to fix one car battery at his shop can run more than $10,000 — more than most consumers willing to pay. Instead, he said, many are choosing to sell or donate their old vehicle for scrap and buy a brand new Tesla.

“It comes to the point where [the car] is almost like a consumable, like a TV,” Benoit said.

Benoit’s experience heralds a problem facing early adopters of EVs, as well as electric micromobility devices like e-bikes and e-scooters: These vehicles contain large, expensive batteries that will inevitably degrade or stop working over time. Refurbishing these batteries can have sustainability benefits, saving energy and resources which would otherwise be used to produce a new one. This is especially important for EVs, which contain very large batteries that must be used for years to charge them carbon emissions associated with making it. But many EV and e-mobility batteries are difficult to repair by design, and some manufacturers actively discourage the practice, citing security concerns. The small number of independent mechanics who repair EV or e-bike batteries struggle to do so affordably due to design challenges, safety requirements, and lack of access to parts.

“There are a lot of batteries in the trash that can be repaired,” says Timoté Rouffignac, who runs a small e-bike battery repair business. Daurema in Brussels, Belgium. But “because they are not made to be repaired, it is quite difficult to suggest a good price.”

A lithium-ion battery in a smartphone contains a single “cell” consisting of a graphite anode, a metal cathode, and a liquid electrolyte that allows lithium ions to move from one side to the other to build up an electrical potential. to wake up An e-bike battery often contains dozens of cells. EV batteries, meanwhile, can contain hundreds to thousands of individual cells, often packaged into “modules” and bundled from there into a battery pack. In addition to cells and modules, electric car and e-bike batteries typically include a battery management system that monitors the battery’s state of health and controls the rate of charging and discharging.

All lithium-ion batteries degrade with use and eventually need to be replaced. But when a battery contains many individual cells and other components, its life span can sometimes be extended through repair, a process that involves identifying and replacing the bad cells or modules and repairing other faulty parts, such as a faulty battery management system. In some cases, a single module is all that needs to be replaced. Swapping out that module, instead of replacing the entire battery, reduces the demand for battery metals like lithium, as well as the carbon emissions associated with manufacturing replacement batteries (or new vehicles). This makes battery recovery “highly desirable for a circular economy” — a system in which resources are conserved and reused — said Gavin Harper, a research fellow who studies battery sustainability at the University of Birmingham in the United Kingdom.

And while not necessarily cheap, repairing batteries can save money. Tyler Help from Cox Motor, which repairs in-warranty EV batteries on behalf of automakers and their dealers across the United States, said that a refurbished EV battery is generally about half the cost of a new one. Since it began offering EV battery repair services in 2014, Cox Automotive estimates it has saved more than a gigawatt-hour of batteries — enough to power about 17,000 new EVs — from being prematurely discarded.

“There are a host of different reasons why recovery is huge [more] beneficial as a replacement,” Helps told Grist.

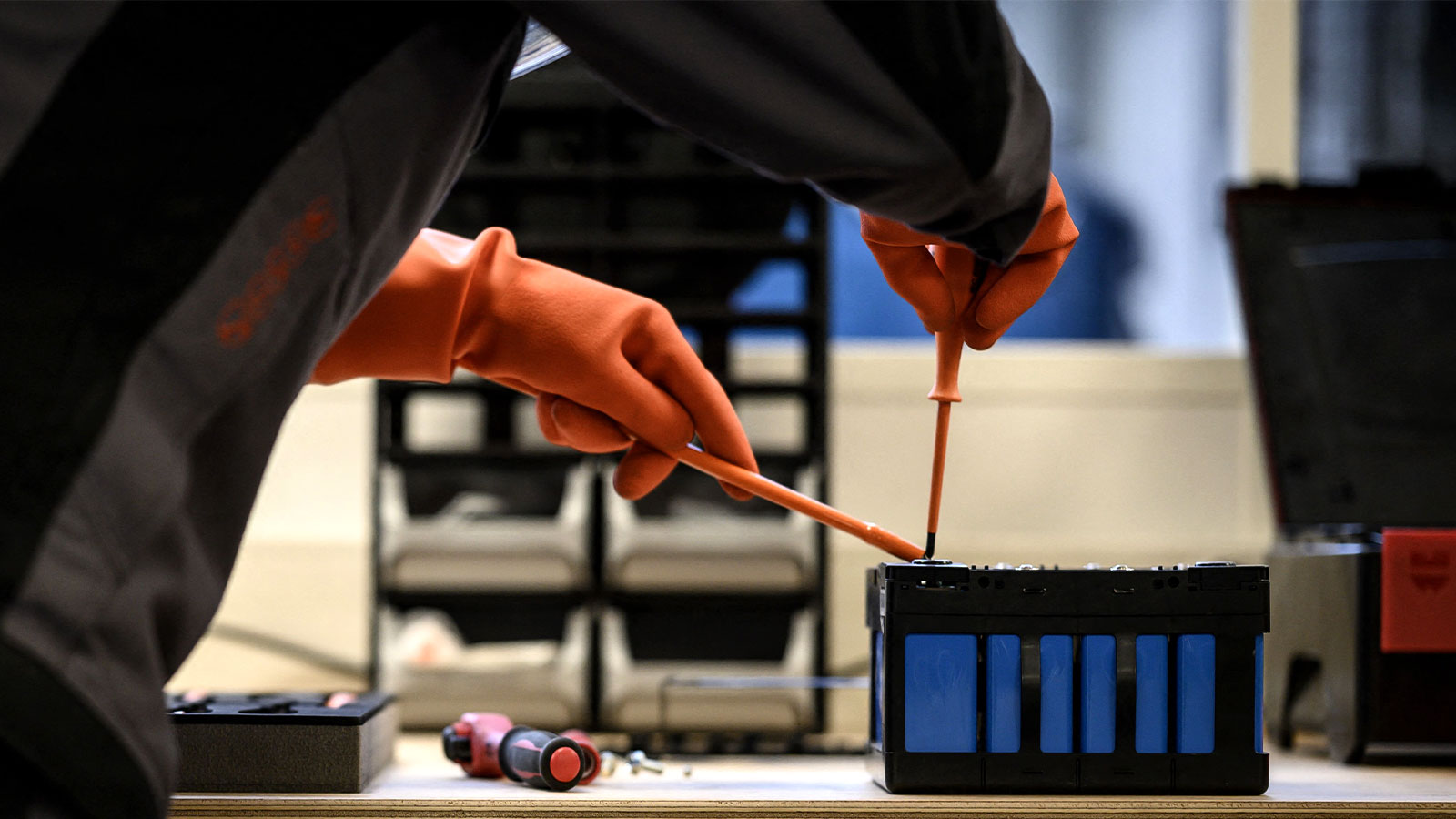

But battery recovery is dangerous and should not be attempted at home or by beginners, experts say. If battery cells are damaged during a repair attempt, it can cause a short circuit that leads to a fire or explosion. If the person attempting the repair is not wearing the correct high voltage gloves, they could get electrocuted. “You’re playing with fire” if you don’t know what you’re doing, said John Mathna, who owns e-bike repair shop Chattanooga Electric Bike Co. management, said, noting that some e-bike batteries “contain enough current to kill someone.”

Loic Venance/AFP via Getty Images

At a minimum, battery repair requires high-voltage training, electrical experience, personal protective equipment and “a basic understanding of the architectures and how the battery works,” Helps said. Those looking to fix EV batteries also need equipment to lift the car off the ground and physically remove the battery, which can weigh thousands of pounds.

“There are very few people who can or even should attempt something like this,” Benoit said.

But even those with the right training often struggle to repair EV or e-bike batteries because of how they are designed. Many e-bike batteries are housed in heavy-duty plastic cases that can be difficult, if not impossible, to open without damaging internal components. Within an e-bike battery, or within individual modules of an EV battery, cells are often glued or welded together, making them difficult or impossible to replace individually. What’s more, if a 2021 report by the European Environment Agency highlighted, some e-mobility batteries contain software that causes the battery to shut down if it detects evidence of unauthorized tampering.

Manufacturers argue that their batteries are designed to promote safety, durability and high performance, which may come at the expense of repairability, and many offer free or discounted replacement batteries within the warranty period (usually about 2 years for major e-bike brands and 8 to 10 years or 100,000 miles for EVs). Proponents of retrofitting, on the other hand, argue that modular designs with reversible fasteners, such as clips or adhesives that can be detached, do not necessarily compromise safety and that the benefits of designing for retrofitting far outweigh the costs.

European policy makers are starting to listen to advocates. In August the European Union adopted a new regulation aimed at promoting battery sustainability. Among other things, this includes a provision requiring that the batteries used in e-bikes and other “light transport” vehicles, such as e-scooters, be repaired down to the individual cell level by independent professionals. The European e-bike industry, which strongly opposed to this provision due to safety concerns, battery certification and legal liability issues, is now grappling with how to comply.

“We are still investigating how the requirements of the new EU battery regulation can be made possible while meeting the applicable safety regulations and our high quality standards,” Bosch told Grist. One challenge for manufacturers, Bosch noted, is the “contradictory development in the US,” which is “moving toward stronger regulations and higher standards for e-bike batteries and systems.”

Indeed, the federal Consumer Product Safety Commission recently announced that it does taking into account regulations for e-bikes and their batteries. It comes after that a recent rash of e-bike battery fires which also prompted a policy response at the local level. The New York City Council recently amended its fire code to prohibit “the assembly or reconditioning of a lithium-ion battery” with second-hand cells from another battery, which repairers sometimes do.

The city too recently enacted a law which requires e-mobility manufacturers to ensure their products’ batteries are certified to the UL 2271 design standard, which is intended to promote safety. Ibrahim Jilani, the global director of consumer technology at UL Solutions – a multinational company that develops safety certification standards for a wide range of industrial and consumer products and materials – said that refurbished batteries can meet this standard. But the company doing the repairs will be required to “keep the design exactly as it was before it needed to be repaired,” Jilani said, including using the same make and model of cells and electronic components. Battery repair shops will also have to submit to UL field inspections four times a year. In general, obtaining this certification will cost repair businesses a little more than $5,000 a year, Jilani said.

Compared to e-bikes, lawmakers have been relatively quiet about EV battery recovery. In the US, there are no specific laws or regulations that address the issue. The EU’s new battery regulation also does not affect EV battery recovery, except to suggest that lawmakers update a separate vehicle regulation “to ensure that those batteries can be removed, replaced and disassembled.”

It’s an idea that GDV, the German Insurance Association, “strongly supports,” a spokesperson told Grist. In October, the group presented the results of a study that found EVs are a third more expensive to repair than similar gas-powered vehicles, a finding it attributes in part to the high cost of repairing or replacing batteries.

“There are many car manufacturers that do not allow battery repair, even in the case of minor damage to the battery case,” a GDV spokesperson told Grist. Car manufacturers sometimes choose to replace the battery if the car has been involved in an accident that caused the airbags to activate. Both practices “will lead to an increase in repair costs,” and ultimately higher insurance premiums, the spokesman said.

New rules on repairability of EV batteries would come at a critical time. Helps, of Cox Automotive, said two trends in EV battery design are running parallel: “Batteries are either becoming very serviceable, or not serviceable at all.”

Some, like the batteries inside Volkswagon’s ID.4, feature LEGO-like modules that are easy to remove and replace. Others, like Tesla’s new 4680 structural battery pack, don’t include modules at all. Instead, all the cells are tied together and tied to the suit itself, a design help describes as “impossible to service.” If a bad cell group is found, the entire battery must be replaced.

“It’s still a fully recyclable battery,” Helps said. “You just aren’t capable of repairing it.”

Tesla did not respond to Grist’s request for comment.