Can metals that occur naturally in seawater be mined, and can they be mined sustainably? An Oakland, California company says yes. And not only does it extract magnesium from seawater – and from waste water generated by industry – it does so in a carbon-neutral way. Magrathea Metals has produced small amounts of magnesium in pilot projects, and with financial support from the US Department of Defense, is building a larger-scale facility to produce hundreds of tons of the metal over two to four years. By 2028, it says it plans to operate a facility that will produce more than 10,000 tons annually.

Magnesium is much lighter and stronger than steel, and it is critical to the aircraft, automotive, steel and defense industries, which is why the government funded the venture. Right now, China produces about 85 percent of the world’s magnesium in a dirty, carbon-intensive process. So finding a way to produce magnesium domestically using renewable energy is not just an economic and environmental issue, it is a strategic one. “With the snap of a finger, China can shut down US steelmaking by ending magnesium exports,” says Alex Grant, Magrathea’s CEO and an expert in decarbonizing the production of metals.

“China uses a lot of coal and a lot of labor,” Grant continued. “We don’t use any coal and [use] a much lower amount of labor.” The method is low cost in part because the company can use wind and solar energy during peak times, when it is cheapest. As a result, Grant estimates their metal will cost about half that of traditional producers working with ore.

Magrathea – named after a planet in the hit novel The Hitchhiker’s Guide to the Galaxy – buy waste water, often from desalination plants, and let the water evaporate, leaving behind magnesium chloride salts. Next, it sends an electric current through the salts to separate them from the molten magnesium, which is then cast into ingots or machine components.

While humans have long extracted minerals and chemicals from seawater – sea salt has been extracted from seawater for millennia – researchers around the world are now broaden their scope as demand for lithium, cobalt and other metals used in battery technology increased. Companies are scrambling to find new deposits in unlikely places, both to avoid orebody mining and to reduce pollution. The next frontier for critical minerals and chemicals appears to be salt water or brine.

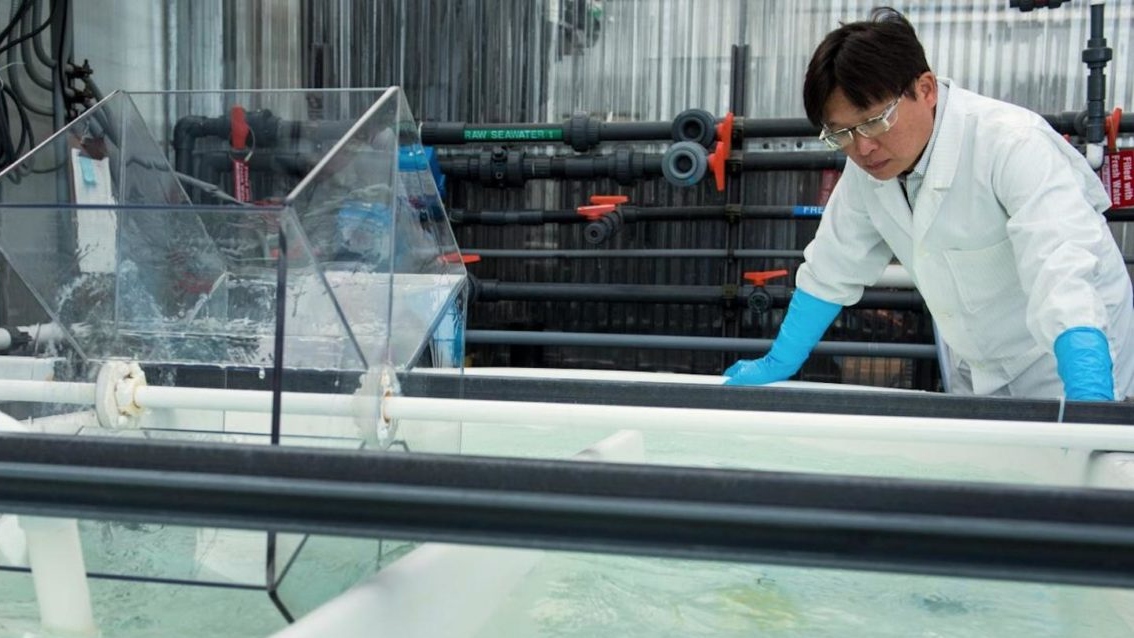

Alex Grant

Brine comes from a number of sources: many new research focus on the potential for extracting metals from brine waste generated by industry, including coal-fired power plants that dump waste into tailings ponds; wastewater pumped from oil and gas wells — called produced water; wastewater from hard rock mining; and desalination plants.

Large-scale brine mining can have negative environmental impacts – for example, some waste will have to be disposed of. But because no large-scale operations currently exist, potential impacts are unknown. Still, the process is expected to have numerous positive effects, notably that it will produce valuable metals without the massive soil disturbance and creation of acid mine drainage and other pollution associated with hard rock mining.

According to the Brine Miners, a research center at Oregon State University, there are about 18,000 desalination plants worldwide that take in 23 billion gallons of seawater a year and either force it through semipermeable membranes – in a process called reverse osmosis – or other methods to separate water molecules from impurities. Every day, the plants produce more than 37 billion liters of brine – enough to fill 50,000 Olympic-sized swimming pools. That solution contains big amounts of copper, zinc, magnesium and other valuable metals.

Disposing of brine from desalination plants has always been a challenge. In coastal areas, detritus plants move that waste back into the sea, where it settles on the seabed and can damage marine ecosystems. Because the brine is so highly concentrated, it is toxic to plants and animals; domestic desalination plants either bury their waste or inject it into wells. These processes further increase the cost of an already expensive process, and the problem is growing just like desoldering plants increase worldwide.

Finding a profitable and safe use for brine will help solve plants’ waste problems and, by using their brine to feed another process, propel them towards a circular economy, in which residues from one industrial activity become source material for a new activity. According to OSU estimates, brine from desalination plants contains $2.2 trillion worth of materials, including more than 17,400 tonnes of lithium, which is essential for making batteries for electric vehicles, appliances and electric energy storage systems. In some cases, extracting brine for lithium and other metals and minerals can make the remaining waste stream less toxic.

Magrathea metals

For many decades, manufacturers have been extracting magnesium and lithium from natural brines. In California’s Salton Sea, which contains enough lithium to supply the nation’s needs for decades, according to a 2023 federal analysiscompanies drilled geothermal wells to generate the energy needed to separate the metal from brine.

And in rural Arkansas, ExxonMobil recently announced that it is building one of the largest lithium processing facilities in the world—a state-of-the-art facility that siphon lithium of brine deep within the Smackover geological formation. By 2030, the company says it will produce 15 percent of the world’s lithium.

Miners largely ignored the minerals found in desalination brine because it was not economical to concentrate them. But new technologies and other innovations created more effective separation methods and allowed companies to focus on this great resource.

“Three vectors are converging,” says Peter Fiske, director of the National Alliance for Water Innovation at the Department of Energy’s Lawrence Berkeley National Laboratory in Berkeley. “The value of some of these critical materials is increasing. The cost of conventional [open pit] mining and exploitation close. And the security of international suppliers, especially Russia and China, is going down.”

There is also an emphasis on – and allocation of money from the Department of Defense, the Department of Energy and elsewhere for – projects and businesses that emit extremely low, zero or negative greenhouse gas emissions and that can be part of a circular economy. Researchers studying brine mining believe the holy grail of desalination — finding more than enough value in its waste brine to pay for the expensive process of creating fresh water — is achievable.

Improved filter technologies can now remove much more, and much smaller, material suspended in brine. “We now have membranes that are selective for an individual ion,” Fiske said. “The technology [allows us] to pick through the garbage heaps of waste water and pick out the high value items.” One of the fundamental concepts driving this research, he says, “is that there is no such thing as wastewater.”

NEOM, the controversial and extremely expensive futuristic city under construction in the Saudi Arabian desert, has assembled a highly regarded international team to build a desalination plant and a facility to mine its waste for minerals and chemicals and to process the amount of material that it should be disposed of to a minimum. of. ENOWA, the water and energy division of NEOM, demands that its selective membranes – which include reverse and forward osmosis – will target specific minerals and extract 99.5 percent of the waste brine’s potassium chloride, an important fertilizer with high market value. The system uses half the energy and requires half the capital cost of traditional methods of potassium chloride production. ENOWA says it is developing other selective membranes to process other minerals, such as lithium and rubidium salts, from waste brine.

The Brine Miner Project in Oregon has created an experimental system to desalinate salt water and extract lithium, rare earth and other metals. The entire process will be powered by green hydrogen, which researchers will create by splitting water’s hydrogen and oxygen molecules apart using renewable energy. “We’re trying for a circular process,” said Zhenxing Feng, who leads the project at OSU. “We don’t waste any parts.”

The concept of exploiting desalination brine and other wastewater is being researched and implemented around the world. At the Delft University of Technology, in the Netherlands, researchers have extracted a bio-based material they call Kaumera from sludge granules formed during the treatment of municipal waste water. Combined with other raw materials, Kaumera – which is both a binder and an adhesive, and both repels and retains water – can be used in agriculture and the textile and construction industry.

Another large-scale European project mentioned Sea4Value, which has partners in eight countries, will use a combination of technologies to concentrate, extract, purify and crystallize 10 target elements from brine. Publicly funded laboratories in the US, including the Department of Energy’s Ames Laboratory, at Iowa State University, and Oak Ridge National Laboratory, in Tennessee, are also investigating new methods for extracting lithium and other materials important to the energy transition from natural and industrial brine. .

At the Kay Bailey Hutchison Desalination Plant in El Paso, Texas, which supplies more than 27 million gallons of fresh water per day from brackish aquifers, waste brine is trucked to an injection well 22 miles away and pumped into an injection well. But first a company called Upwell Waterwhich has a facility near the desalination plant, wrings more potable water from the brine and uses the remaining waste to produce gypsum and hydrochloric acid for industrial customers.

There are obstacles to successful brine mining projects. Christos Charisiadis, the brine innovation manager for the NEOM portfolio, identified several potential bottlenecks: high initial investment for processing facilities; a lack of transparency in innovation by the water industry, which can mask problems with their technologies; poor understanding of possible environmental problems due to a lack of comprehensive life cycle assessments; complex and inconsistent regulatory frameworks; and fluctuations in commodity prices.

However, Nathanial Cooper, an assistant professor at the University of Cambridge who studied metal recovery from a variety of industrial and natural brines, sees its prospects as promising as environmental regulations for a wide range of industries become increasingly stringent.

“Companies that produce wastewater will do more and more to ensure that the wastewater they dispose of is clean of pollutants and hazardous materials,” he said. “Many companies will be forced to find ways to recycle this material. There is strong potential to recover very valuable materials from wastewater and contribute to a circular economy.”